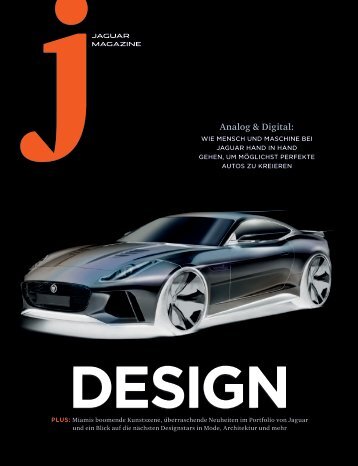

Jaguar Magazine DESIGN – English

- Text

- Jaguar

- Formula

- Racing

- Arts

- Rear

- Rover

- Architecture

- Designers

- Interior

- Accessories

2002 JAGUAR XJ At the

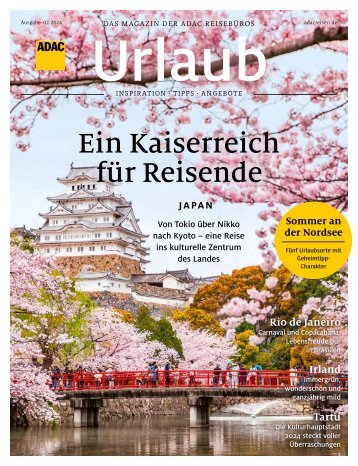

2002 JAGUAR XJ At the start of the 21st entury the aluminiumintensive XJ shed 200kg in the name of efficiency 1948 JAGUAR XK120 Lightweight as a virtue was pioneered by Jaguar in the 40s on this aluminium roadster 2010 C-X75 This electric supercar concept was a hotbed of future-propulsion ideas and featured in Bond’s Spectre FUTURE POWER JAGUAR’S EMISSION REDUCTION MISSION IS GATHERING PACE. READ ON TO CATCH UP WORDS: Stuart Birch 2016 FORMULA E To accelerate its future electric road car plans, Jaguar joins the Formula E grid in the autumn 2014 INGENIUM ENGINES Jaguar’s great new family of diesel and petrol engines launched in the XE delivers high peformance with low fuel consumption and CO 2 With the end of production of the internal combustion engine now pinpointed to the year 2050 – through a European Union directive – the car industry has a clear marker to aim for. And rest assured, Jaguar has a plan to transition its methods of propulsion to deliver hugely lower emissions – with the eventual goal of eradicating them – just as smoothly as its current engine line-up accelerates. The challenge, and opportunity, is to do so while ensuring that every emerging model is true to Jaguar’s individuality in a carbon-conscious world. Powertrain (engine and transmission) development remains the salient but by no means only focus for energy saving, as Jaguar’s research and development director, Dr Wolfgang Epple explains: “Environmental innovation is at the heart of our business strategy. We know that the 72 j THE DESIGN ISSUE

TECHNOLOGY creation of vehicles which consume less fuel, emit less CO 2 and are more sustainable, cannot be achieved by the introduction of hybrid and battery powertrains alone.” Innovative complementary technologies are a must to achieve essential integrated solutions, he says. These include the reduction of energy-wasting friction in engines, cutting on-board energy requirements from things like heating and ventilation systems, improving aerodynamics and using lighter-weight materials like aluminium. Jaguar has a strong history taking this lightweight approach, from the initial XK120s launched as far back as 1948 to the 2002 all-aluminium-bodied XJ which helped it to save 200kg over its previous model. By making cars lighter, less fuel is needed to power the car forward and fewer emissions result. Jaguar has continued this approach in successive models since then, and is without question, a world leader in the production of aluminium-intensive cars. More recently, Jaguar has stepped up its efforts again. “In 2008 we began a multi-billion pound research programme,” says Dr Epple, “to directly address the challenge of significantly reducing the carbon footprint of our high-performance premium vehicles while maintaining the attributes of luxury, performance, refinement and comfort that our customers expect. While hybrid and pure electric research programmes are in place, development of internal combustion technology continues apace. The latest four-cylinder Ingenium petrol and diesel engines from Jaguar’s all-new Wolverhampton manufacturing plant, power the XE and XF. They demonstrate how to meld the need for smaller power units and deliver excellent power outputs with low CO 2 emissions and fuel consumption (indeed the 163hp XE diesel’s 99g/km put it first in its segment at launch). Advanced transmissions are an essential complement to this process, carefully matching power output to achieve greater efficiency while ensuring that all Jaguars provide driver satisfaction. Jaguar is also harvesting energysaving solutions. “We are researching a range of technologies including how we could mix carbon fibre with flax,” reveals Dr Epple. Flax, as a food and fibre crop, provides an alternative material that is one element within the “ THE CHALLENGE AND OPPORTUNITY IS TO ENSURE THAT EVERY EMERGING MODEL IS TRUE TO JAGUAR’S INDIVIDUALITY IN A CARBON- CONSCIOUS WORLD ” multi-partner CARBIO project of which Jaguar is a member. The project is working on all sorts of structures for use inside cars with reduced weight, cost, environmental impact and also less noise, vibration and harshness (also known as NVH). All of which means less sound deadening material will be required and makes extra weight savings possible. Hybrid vehicles – using a combination of internal combustion engines and electric motors – are another solution to reducing emissions and fuel consumption and Jaguar is now looking far into the 2020s at new powertrains that could deliver the essential combination of performance, luxury, packaging and handling in keeping with the brand’s values, while delivering a further step change in fuel consumption and emissions reduction. One of these is the radial flux machine, part of another collaborative research project that receives funding from the British Government-backed Innovate UK programme. Mike Richardson, Jaguar Land Rover’s chief technical specialist, says: “Slim, light and extremely powerful, they produce up to twice the power of today’s production technology and would allow us to produce virtually any hybrid or battery vehicle configuration.” Jaguar’s 2010 C-X75 concept – more recently turned into the baddie-mobile for 2015’s James Bond Spectre film – has an electric motor for each wheel and tiny Bladon gas turbine engines to provide range extension up to a remarkable 560 miles. That concept already indicates how the company could combine sustainable technology with high performance driving fun, emitting just 28g/km of CO 2 but also dispatching 0-62mph in 3.4 seconds. Forward-wind to 2016 and Jaguar’s commitment to a return to racing later this year via the fully-electric Formula E series (see our separate feature on p16), and it becomes increasingly clear that the brand is serious about this technology and electrically-propelled production cars to follow. As Nick Rogers, group engineering director for Jaguar Land Rover, concludes: “Formula E will give us a unique opportunity to further our development of electrification technologies and test our advanced technologies under extreme performance conditions.” In other words, Jaguar’s future powertrain path is well under way and promises to be as exciting as its past. THE DESIGN ISSUE j 73

- Seite 1 und 2:

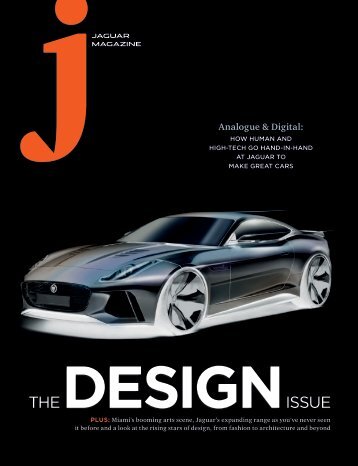

Analogue & Digital: HOW HUMAN AND H

- Seite 3 und 4:

Image Image courtesy courtesy of Ho

- Seite 5 und 6:

THE RUSH Gaining traction As Jaguar

- Seite 7 und 8:

16 50 58 08 Ignition In keeping wit

- Seite 9 und 10:

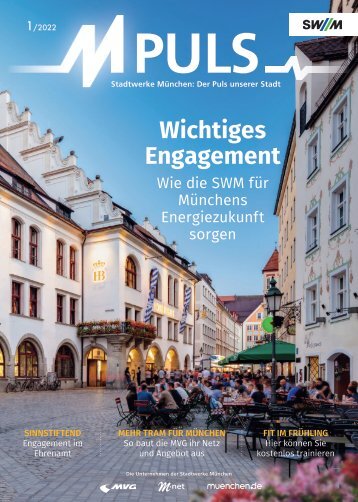

THE STAY COTTON HOUSE HOTEL BARCELO

- Seite 12 und 13:

THE AMERICAS (Un)plug and play Disc

- Seite 14:

ASIA KOREAN FRIED CHICKEN You may k

- Seite 17 und 18:

We have an exciting future and elec

- Seite 19 und 20:

PEN TO PAPER This is how every Jagu

- Seite 21 und 22: PHOTOGRAPHY: LKJDÄLKJDF KJLÄKJ Ö

- Seite 23 und 24: INFOTAINMENT GURU Alister Whelan ta

- Seite 25 und 26: MARK WHITE, 56 Day job: Chief engin

- Seite 27 und 28: WITH THE F-PACE WE STARTED OFF WITH

- Seite 30 und 31: THE RELATIONSHIP BETWEEN DESIGN AND

- Seite 32 und 33: “If you look at the F-PACE the wh

- Seite 34 und 35: TRAVEL Miami Nice FAST-BECOMING THE

- Seite 36 und 37: TRAVEL MIAMI HAS RESONATED IN THE P

- Seite 38 und 39: TRAVEL “HERE IN MIAMI THERE’S A

- Seite 40 und 41: TRAVEL ART ON THE WATER Above: The

- Seite 42 und 43: The power of design before and afte

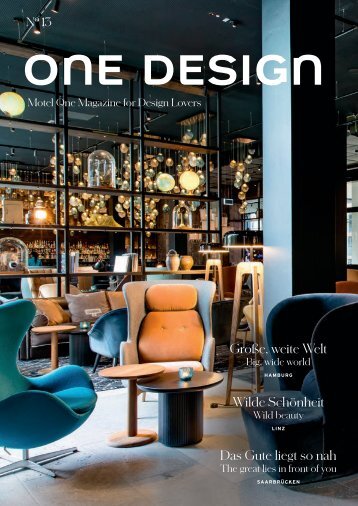

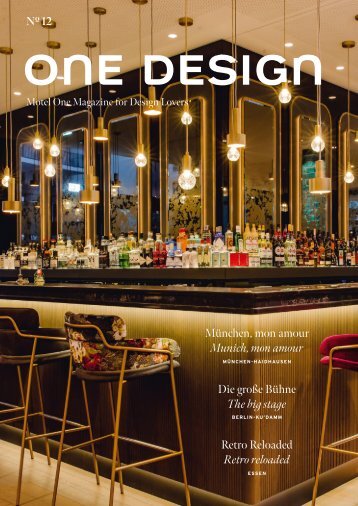

- Seite 44 und 45: CULTURE Design stars FROM ARCHITECT

- Seite 46 und 47: CULTURE HOTEL DESIGN SPECIALIST: AN

- Seite 48 und 49: CULTURE Soh’s work is fascinating

- Seite 50 und 51: DESIGN Performance ART 1959 FROM TH

- Seite 52 und 53: DESIGN F rom its earliest days - be

- Seite 54 und 55: DESIGN 1972 RACING PEDIGREE was a r

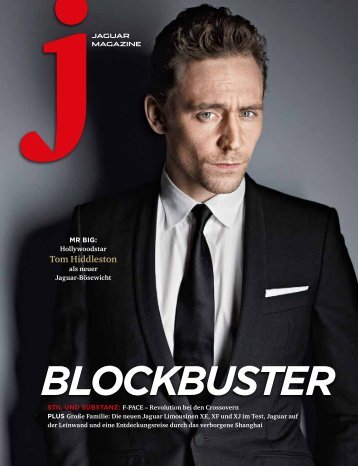

- Seite 56 und 57: PEOPLE An extraordinary hero IT TAK

- Seite 58 und 59: GROUP TEST QUITE THE QUINTET Jaguar

- Seite 60 und 61: GROUP TEST AWD’S NOT ONLY SAFER I

- Seite 62 und 63: GROUP TEST SEE (AND FEEL) THE DIFFE

- Seite 64 und 65: FIRST DRIVE The ultimate F-TYPE WE

- Seite 66 und 67: GALLERY Inspired by nature MILLIONS

- Seite 68 und 69: SHINKANSEN BULLET TRAIN BY EIJI NAK

- Seite 70 und 71: GALLERY SYNAPSE CHIP BY IBM Artific

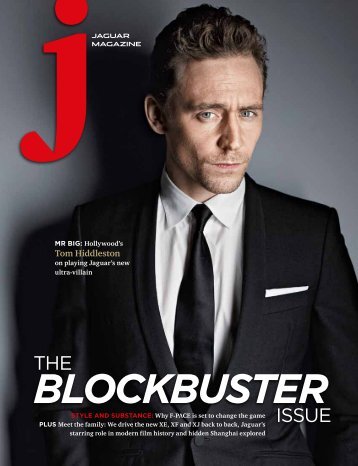

- Seite 74 und 75: Me and my Jaguar FOR OUR DESIGN-THE

- Seite 76 und 77: JAGUAR MAGAZINE THE DESIGN ISSUE Ed

- Seite 78 und 79: PROMOTION BECOME AN ICE-DRIVING MAS

Unangemessen

Laden...

Magazin per E-Mail verschicken

Laden...

Einbetten

Laden...

IMPRESSUM

STORYBOARD GMBH

WILTRUDENSTRASSE 5

D-80805 MÜNCHEN

FON +49 (0)89 - 9010976 - 10

FAX +49 (0)89 - 9010976 - 68

MAIL: INFO@STORYBOARD.DE

DATENSCHUTZ

AG MÜNCHEN HRB 192756

GESCHÄFTSFÜHRER:

DR. MARKUS SCHÖNMANN, CHRISTINE FEHENBERGER, MARIE BRESSEM

USTID: DE 278105991